GRAE-500-GRAE Sound out

Sound Insulation/Sound Insulation/Suction Paint

GRAE SOUND OUT

Product Overview

– Porous ceramic powder and highly elastic acrylic emulsion and sunscreen

– Addition of anti-aging agents, antibacterial agents, and natural additives

– State-of-the-art eco-friendly coating that simultaneously exhibits complex functions such as sound insulation, sound insulation, sound absorption and insulation

Product Features

Excellent soundproofing effect with dense matrix structure of powder and acrylic emulsion

Porous ceramic materials, highly elastic resins, and fillers of various structures form many spaces in the paint film to block the sound of sound.

Excellent weather resistance and adhesion, and simple construction as a water-based eco-friendly product

Physical properties

| Category | Contents | Item | Contents |

|---|---|---|---|

| Main component | Porous ceramic, highly elastic acrylic emulsion | Theoretical coating thickness | 1.3m²/L |

| Type | Hydrophilic | shape | One component |

| Solid content | 70~75% | Volume solids | 70+/-3% |

| Importance | 0.7 | Dry film thickness | 0.4~ 0.6mm or more |

| PH | 6.8~7.0 | Color / Paint appearance | White / matte, semi-gloss |

Test result

| Test Items | unit | Sample classification | Result | Test Methods |

|---|---|---|---|---|

| Thermal conductivity (average temperature : 20℃±3℃) | W/(m.k) | - | 0.227 | KS L 9016 : 2010(Plate heat flow method) |

| Adhesion strength | N/mm2 | - | 1.08 | KS F 4040 : 2004 |

| Length change rate | % | - | -0.2 | KS F 4040 : 2004 |

Construction method

– Removes laitance, oil and other contaminants from the bottom surface, and fills grooves and cracks with elastic putty or quick tie

– Apply graphite insulation evenly with brush, roller, spray, etc.

– The repainting interval should be applied after confirming that it has been dried after 1~5 hours at room temperature, and applied at least 3 times.

– When dilution, the water should be within 5% and sufficiently stirred for at least 5 minutes using a low speed stirrer.

– When thickness is required, spray or plaster after stirring the exclusive powder and liquid in a ratio of 1: 3 to 5(powder)

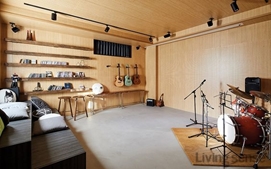

Construction site

Blend

Application

Precautions

Construction site utilization

Building exterior

Inside the building

library

auditorium

Music room

Movie Theaters

Product comparison table (Sound Proof)

| Category | Polyester sound absorbing material | Wood-shaped sound-absorbing board | Art board | GLASS WOOL | Urethane (sponge) | Soundproof paint |

|---|---|---|---|---|---|---|

| Ingredient | A product that is fused with polyester fiber | A product formed by mixing wood wool (poplar) with inorganic materials such as cement | Product made into a board shape by pressing polyester fiber | A product made of fiber by melting glass in an electric furnace and extruding it into pores | Product made by polymerizing and foaming Lsocynte and Polyother | A state-of-the-art eco-friendly product that simultaneously exhibits complex functions such as sound insulation, sound insulation, sound absorption and insulation. |

| Sound absorption Characteristics | NRC = 0.577 (25T) 500HZ에서 0.570 | NRC = 0.37 (25T) 500HZ에서 0.155 | NRC = 0.32 (9T) 500HZ에서 0.14 | NRC = 0.75 ~ 0.80 | NRC = 0.75 ~ 0.80 | - |

| Advantages | Sound absorption, sound insulation effect is moderate Eco-friendly and recyclable Excellent surface smoothness | Excellent effect on sound absorption and sound insulation Excellent surface smoothness | Excellent effect on sound absorption and sound insulation Excellent surface smoothness | Sound absorption, sound insulation, effect is moderate Used as insulation. | Low price, various designs available Sound absorption, sound insulation effect is moderate | Excellent soundproofing effect by preventing the reverberation of sound Mercury's eco-friendly product |

| Disadvantages | Impossible to restore when surface is peeled Poor surface condition causes contamination | The price is high A lot of dust is generated during cutting or due to aging and impact Sound absorption decreases during painting | Cannot be directly mounted on the base of the structure It should be constructed after finishing the gypsum board so that no defects occur. | More than 50mm, the sound absorption rate increases, but there is no significant difference. Dust generation | Hazardous gas generation in case of fire Vulnerable to UV rays. | Need to secure minimum thickness for sound insulation, sound insulation, and sound absorption |